Footings are considered as the most crucial part of a structure. The foundation delivers the entire load of the structure to the soil. This spreadsheet can be used to design rectangular or square footing.

This spreadsheet consists of five sections which are explained below :-

Input Section Rectangular Footing Design Spreadsheet

Under this section, most of the inputs should be put in because there are some options which can be inputted in due course. Cells for inputting data are demonstrated with a filled background. At the location where there exists some advised value but it is possible for a user to modify the value for instance. “Factor of safety” a default value is put in and an input place is set after “or” where needed value can be put in and value that will be utilized again is illustrated after “use”.

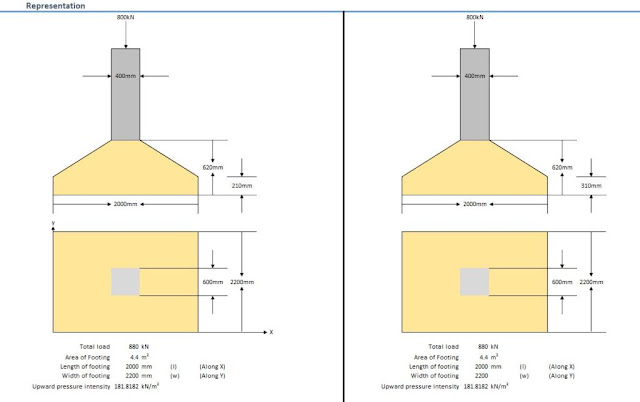

Representation Section of Rectangular Footing Design Spreadsheet.

The 2nd part of the spreadsheet is representation where a footing diagram is represented and different types of dimensions are also entered.

In this part amount of steel reinforcement along both the direction is worked out.

Check Section of Rectangular Footing Design Spreadsheet

In a foundation, it becomes very crucial to verify the safety against shear forces at both the vial section. When there exists a shear failure, it is highlighted with conditional formatting in the spreadsheet.

To download the spreadsheet, click on the following link.

http://ccivilengineer.com/spreadsheet-for-designing-rectangular-footing/

This spreadsheet consists of five sections which are explained below :-

Input Section Rectangular Footing Design Spreadsheet

Under this section, most of the inputs should be put in because there are some options which can be inputted in due course. Cells for inputting data are demonstrated with a filled background. At the location where there exists some advised value but it is possible for a user to modify the value for instance. “Factor of safety” a default value is put in and an input place is set after “or” where needed value can be put in and value that will be utilized again is illustrated after “use”.

Representation Section of Rectangular Footing Design Spreadsheet.

The 2nd part of the spreadsheet is representation where a footing diagram is represented and different types of dimensions are also entered.

|

| spreadsheet for rectangular footing design |

In this part amount of steel reinforcement along both the direction is worked out.

Check Section of Rectangular Footing Design Spreadsheet

In a foundation, it becomes very crucial to verify the safety against shear forces at both the vial section. When there exists a shear failure, it is highlighted with conditional formatting in the spreadsheet.

To download the spreadsheet, click on the following link.

http://ccivilengineer.com/spreadsheet-for-designing-rectangular-footing/